JEC Trading offers a lineup of energy-saving products to match the client's environment and facilities.

Consultants with specialized expertise will propose energy-saving products that fit the client's situation and needs.

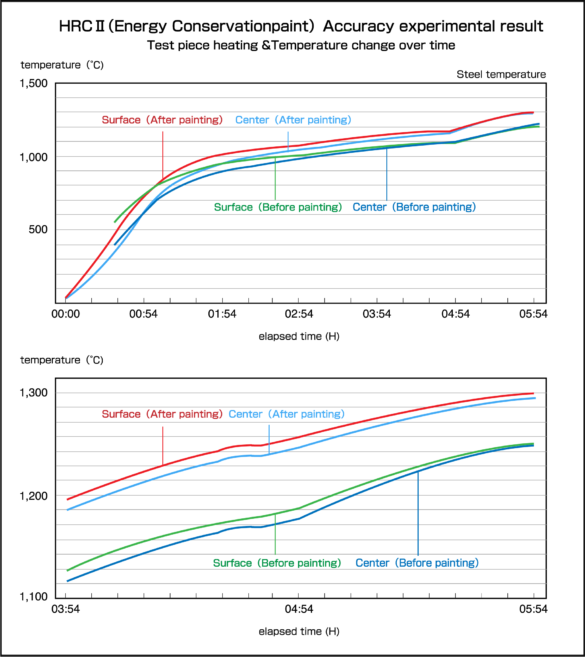

HRC II (Heat Radiation Coating) is a coating material that reduces the fuel cost of various industrial kilns. It was developed by the Japan Heat Radiation Materials Research Institute, and is based on reduced titanium oxide.

Features

■High energy-saving performance.

High energy-saving effect in a wide temperature range (700-1350°C).

■Shortening of temperature rise time

■Water-soluble, odorless, and pollution-free

Titanium dioxide is approved as a cosmetic raw material and food additive, and is not toxic in any way. It does not emit toxic gases either.

■Protective effect on furnace materials

Protects refractory bricks and castables, thus extending the life of the furnace. When applied to ceramic fiber walls, it also prevents fluffing.

■Low cost

Significant cost reduction in terms of high energy saving effect and durability of the furnace.

■Even coating

By applying it to the entire surface of the furnace wall, the radiation rate is evenly increased and the object can be burned evenly.

Effects

■Reduce 5 to 8% in the case of furnaces for steel and nonferrous metals.

■Reduce 2 to 4% in the case of furnaces for oil refining and petrochemicals.

*Subject to change depending on furnace structure and operating conditions.

Applications

■Steel, metals, nonferrous metals, petrochemicals, electricity, automobiles, and ceramics-related fields.

Verification Results

201 Koto Building, 4-10-1 Hatchobori, Chuo-ku, Tokyo 104-0032, Japan